perforated roof sheet

Latest articles

perforated roof sheetAre you familiar with galvanized silk mesh? Do you know what to pay attention to in the process of use?

...

perforated roof sheet 【perforated roof sheet】

Read Moreperforated roof sheet

...

perforated roof sheet 【perforated roof sheet】

Read More2.25*2.25mm indicates that the two strands are 2.25mm silk, and the thorn thread is also 2.25mm silk;

perforated roof sheet...

perforated roof sheet 【perforated roof sheet】

Read More

perforated roof sheet1. Used for mountain farming, road isolation, large farming enclosure protection, it is recommended that you choose 3mm wire diameter products.

...

perforated roof sheet 【perforated roof sheet】

Read Moreperforated roof sheet

...

perforated roof sheet 【perforated roof sheet】

Read Moreperforated roof sheet

...

perforated roof sheet 【perforated roof sheet】

Read Moreperforated roof sheet

...

perforated roof sheet 【perforated roof sheet】

Read Moreperforated roof sheet

...

perforated roof sheet 【perforated roof sheet】

Read More

perforated roof sheetBridge protection system generally do not need to be specially installed special drainage system, the use of hexagonal mesh made of gabion mesh box, the inside of the filler are selected stones, these stones are not easy to wear, and between the stones and stones will retain some gaps, so it is very good to meet the drainage requirements.

...

perforated roof sheet 【perforated roof sheet】

Read More

perforated roof sheetAdvantages: The cost of hot dip galvanized rust prevention is lower than that of other paint coating. In suburban environment, the standard hot-dip galvanized rust prevention thickness can adhere to more than 50 years without repair. In urban or offshore areas, the standard hot-dip galvanized rust protection layer can last 20 years without repair. Galvanized layer and steel is a metallurgical connection, into a part of the steel surface, so the durability of the coating is more reliable.

...

perforated roof sheet 【perforated roof sheet】

Read More

Popular articles

The bonding and anchoring function between cold wire drawing and cold rolled ribbed steel bar and concrete is outstanding. Therefore, when used in components, the phenomenon of cracking of component anchorage area and damage caused by steel wire slip is fundamentally eliminated, and the load-bearing ability and anti-cracking ability of component end are improved. In reinforced concrete structure, the crack width is smaller than that of circular steel bar or even that of hot rolled thread bar.

Now it is more used in the binding of the construction industry. Compared with ordinary wire, it is also softer and has better luster. Use in daily life does not need to carry out maintenance and maintenance, saving a lot of time, but also save the cost of maintenance and maintenance. Annealed wire has good stability, good corrosion resistance, greatly prolonging the service life. There are many kinds, which can be selected according to different uses. The device for making annealed wire is simple, and the utilization rate of the device is improved. The material properties of annealed wire can meet different processing needs.

In view of this situation, many manufacturers are committed to ensuring the corrosion resistance of titanium and titanium alloy under the premise of increasing the hardness of titanium alloy, and surface carburizing is one of the typical processing technology means. Similar to the surface carburizing treatment of steel, the surface carburizing treatment of titanium alloy is to make the active carbon atoms, diffusion to the internal of titanium alloy, the formation of a certain thickness of higher carbon content of the carburizing layer, after quenching and tempering, so that the surface layer of the workpiece to obtain high carbon content of titanium alloy wire.

- 5, play; Appreciation and pan touch. Light touch, over time, the cage will naturally precipitate the traces of time and history and vicissitudes of life. This process does not affect the normal use of the cage. However, it is necessary to maintain the cage continuously and not to use it to the end.

Latest articles

-

Two is to pay attention to the storage and use of galvanized wire products, according to the actual environmental standards to choose different specifications of galvanized wire products;

-

Post time: 23-09-22 -

The size of the galvanized layer of galvanized iron wire is related to the anti-corrosion ability and application effect of galvanized wire. The thickness of the galvanized layer of the general standard galvanized wire products should be tested after the product is formed. There are three specific test methods. Weighing method and cross section microscopy method are destructive experimental methods, and magnetic method is a relatively rigorous non-destructive method, but the measurement steps and requirements are relatively high, so they are rarely used in specific applications. The first two methods are intuitive and common methods.

-

Galvanized wire is divided into hot dip galvanized iron wire and galvanized iron wire according to the production process. It has the characteristics of high tensile strength, good softness, zinc layer uniformity, corrosion resistance, beautiful color, good smoothness, strong adhesion and corrosion resistance. Hot dip galvanizing has better protective properties than electric galvanizing, so it is an important protective coating for steel parts used in harsh working conditions.

-

As we all know, the use of hexagonal net for protection can protect the natural environment while protecting the bridge, which can not only green the ecological environment, but also prevent soil erosion.

-

Small iron wire is very useful in our life, basically a lot of things will use iron wire, and iron wire can also be made into a lot of crafts, making ordinary iron wire become more aesthetic and artistic sense. Of course, the iron wire in the process of use, there will be rust, so galvanized black iron wire in the storage process, it is necessary to master the correct method.

Links

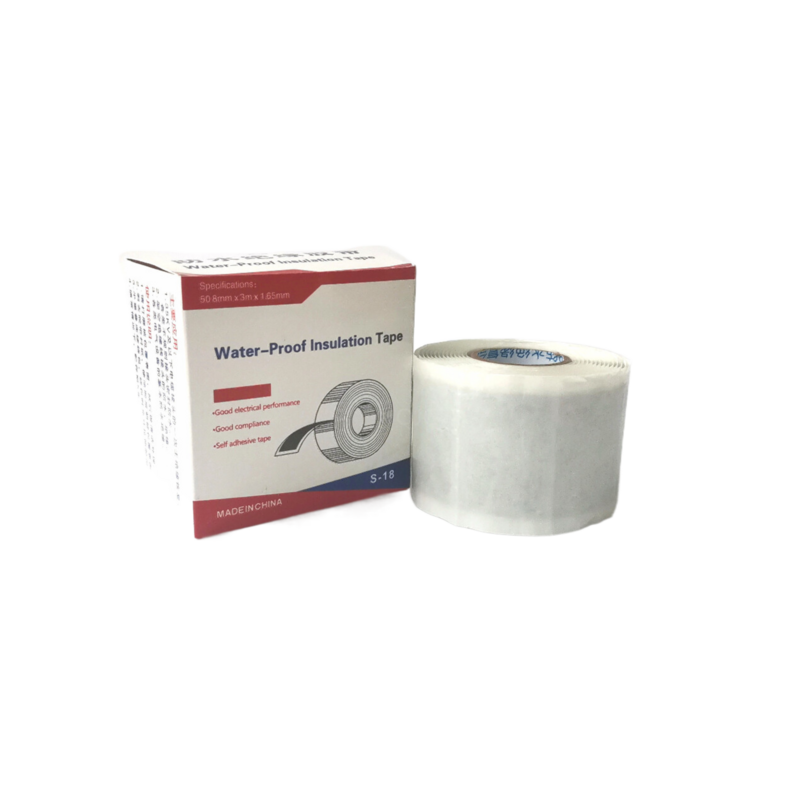

- Furthermore, rubber insulation tape is often employed in industrial settings where harsh conditions prevail. Factories, construction sites, and manufacturing plants can benefit from its robustness and resilience. It can withstand extreme temperatures, vibrations, and mechanical wear, ensuring continuous protection for electrical equipment.

- Butyl rubber, also known as isobutylene-isoprene copolymer, is a blend of isobutylene and isoprene molecules. Its production involves the polymerization process, where these two monomers combine to create a material with outstanding flexibility, waterproofing capabilities, and excellent resistance to oxygen, ozone, and chemicals. These inherent qualities are what make butyl tape rubber an ideal choice for applications requiring airtight and watertight seals.

Advantages of Polyethylene:

- Despite its simplicity, black floor marking tape's impact is profound. Its installation is quick and non-disruptive, requiring minimal downtime. It's also cost-effective compared to painting or other permanent marking methods. Regular replacement or repositioning is straightforward, allowing for adaptable floor plans as needs change.

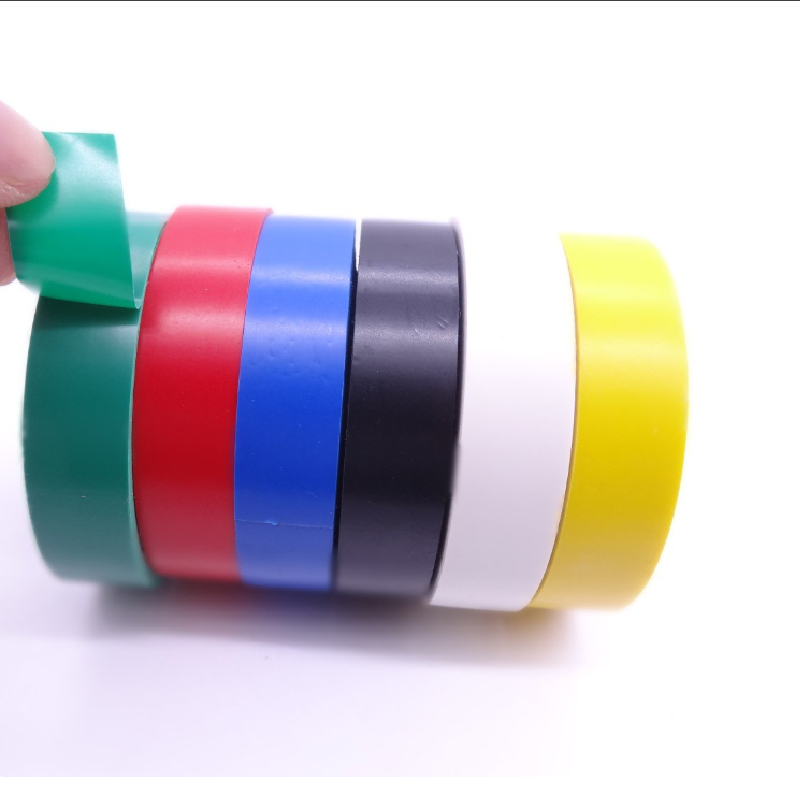

- One of the key benefits of PVC insulation tape black is its ability to provide electrical insulation. This means that it can protect wires and cables from short circuits and other electrical hazards. The black color of the tape offers UV resistance, making it suitable for both indoor and outdoor use.

Amalgamating tape is a unique and versatile solution for various sealing and bonding needs. One of the most popular brands of amalgamating tape is the 3M amalgamating tape, known for its high quality and reliability.

- In conclusion, fireproof tape for drywall is an essential tool for anyone who wants to increase the fire resistance of their walls. By following these simple steps, you can help protect your home or business from the devastating effects of fire.

Is Polyethylene Tape waterproof?

We are pleased to stock a number of different self-fusing tapes. All are electrically insulating though some are often used for sealing work (e.g. fixing a leaking hose) in addition to electrical applications.

What is electrical tape?

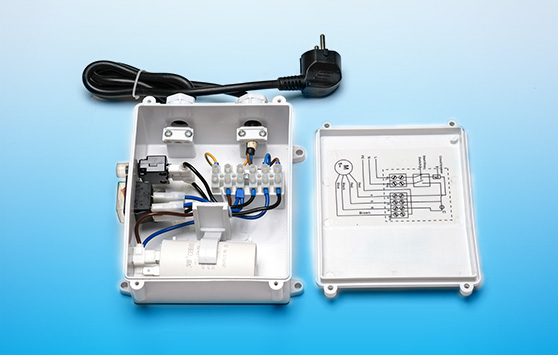

What Is a Well Pump Control Box and How Does It Work?

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors.

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors.ELITE TAPE IS YOUR TRUSTED SOURCE FOR SINGLE COATED TAPES

One of the most significant advantages of butyl rubber is its low permeability to air and other gases. This attribute is particularly valuable in applications where maintaining an airtight seal is critical. Additionally, butyl rubber is resistant to UV radiation, oxidation, and aging, allowing it to withstand harsh environmental conditions without degrading.

Its peel-and-stick application eliminates the need for messy liquids or complicated tools Its peel-and-stick application eliminates the need for messy liquids or complicated tools

Its peel-and-stick application eliminates the need for messy liquids or complicated tools Its peel-and-stick application eliminates the need for messy liquids or complicated tools gray flex seal tape. Simply cut to size, remove the backing, and press firmly onto the surface. The tape adheres instantly, creating a strong bond that resists peeling, tearing, or cracking.

gray flex seal tape. Simply cut to size, remove the backing, and press firmly onto the surface. The tape adheres instantly, creating a strong bond that resists peeling, tearing, or cracking.In addition to organization and protection, a wiring loom wrap also helps to maintain the integrity of the electrical system by preventing moisture, dirt, and debris from infiltrating the wires. This is especially important in an automotive environment, where the wiring is exposed to a wide range of harsh conditions, such as extreme temperatures, vibrations, and chemicals.

4. Versatility and Applications

When it comes to car maintenance, one important aspect that is often overlooked is the car harness tape. This small but crucial component plays a significant role in ensuring the smooth functioning of your vehicle's electrical system.

They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs

They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs expansion joint foam strip. This makes them an ideal choice for buildings with strict energy efficiency requirements.

expansion joint foam strip. This makes them an ideal choice for buildings with strict energy efficiency requirements.Synthetic rubber

diall self amalgamating tape. It serves as a silent hero in construction sites, where it binds beams and supports structures, often going unnoticed until its contribution is significant. In the electronics industry, it provides an insulating layer while ensuring components are securely fastened.

diall self amalgamating tape. It serves as a silent hero in construction sites, where it binds beams and supports structures, often going unnoticed until its contribution is significant. In the electronics industry, it provides an insulating layer while ensuring components are securely fastened.